“Spitting image”? Not really! Inconspicuous but detrimental: poor practice affecting optical fiber deployment

Have you experienced this before? The infra network is installed, cables are connected and coiled in accordance with the rules, the connectors are installed properly, tests have been conducted and validated… and few days or weeks later, the connectors are found to be unstable, or a significant loss of a few decibels is detected: the signal has been lost!

You activate the quality action plan: at first glance, the connectors appear to be defective. After several measurement tests, site visits to check the connections and hours spent exchanging with technicians, the quality experts identify the source of the problem: saliva-related pollution!

This recurrent problem has become apparent over the years. To get the results of installation connection tests right the first time, technicians put saliva on the plugs. This trick used to enable the passage of the signal even if the contact of fiber cores is not perfect, is passed on from one technician to another during internal training.

Saving time during installation?

Once the technician has completed installation, he/she makes a measurement to check whether the equipment is working properly. He/she must of course start over if the results are not satisfactory.

If, for example, the measurements are not compliant because of a damaged launch fiber plug (in particular marks on the surface of the launch fiber plug), the saliva deposit compensates for the spaces between optical contacts and makes the RL (Return Loss) of the measurement consistent with the reflectometer measurement.

This helps achieve a quicker and better result at the time of the test.

This result gives the impression that the saliva deposit is a benign and beneficial operation. But in fact, the connector shows significant losses and a poor reflectometer result during additional measurements or commissioning, once saliva has dried. Saliva damages the optical contacts and, in particular, acts as a filter between said contacts, thereby preventing high speed.

Conditions for an optimal optical connection

To ensure effective optical connection, the two plugs installed in an adapter must be perfectly aligned and in contact.

Reminder:

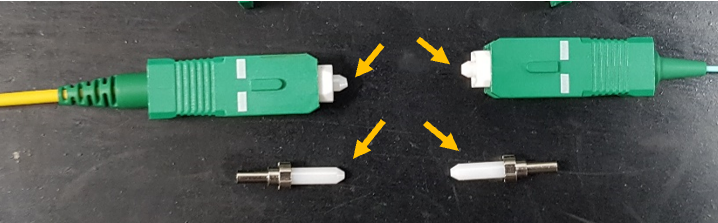

Plug: male part of the patchcord or pigtail for optical connection, which features a ceramic ferrule (yellow arrows)

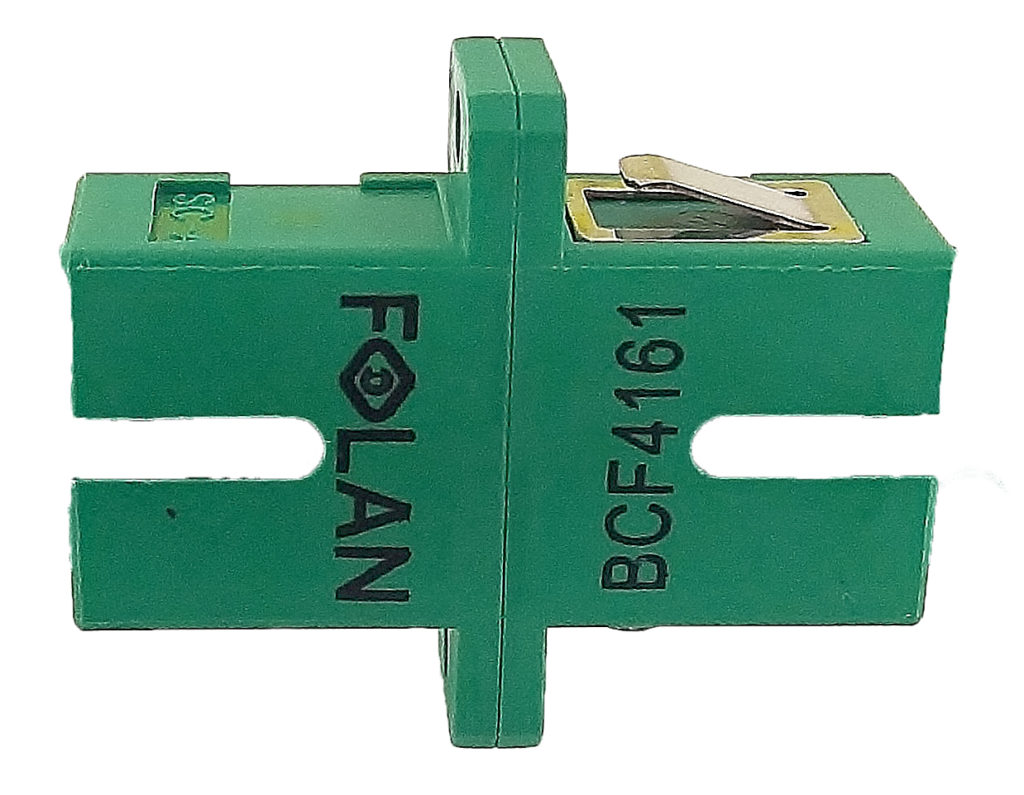

Adapter: female/female part for optical connection

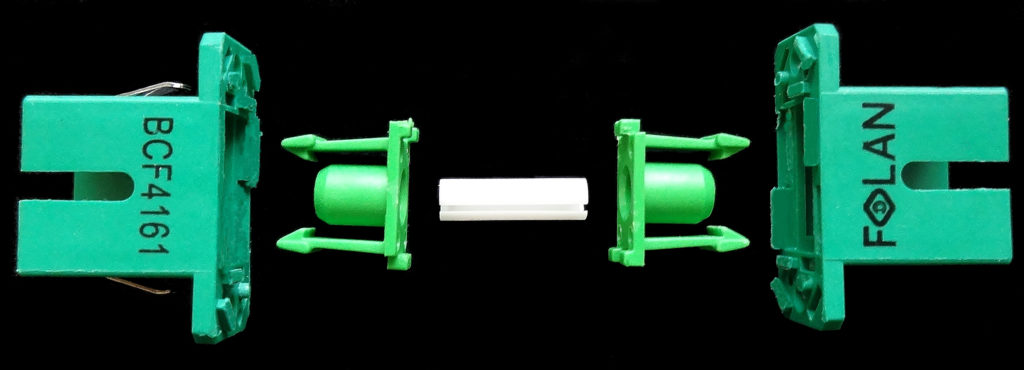

Exploded view of the adapter

Connector: set of 2 plugs and one adapter, creating the optical connection

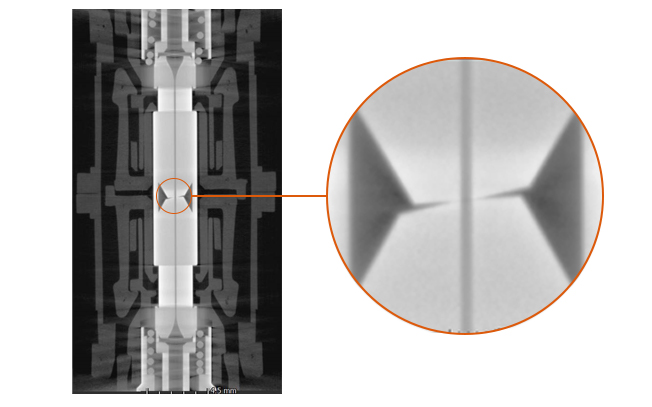

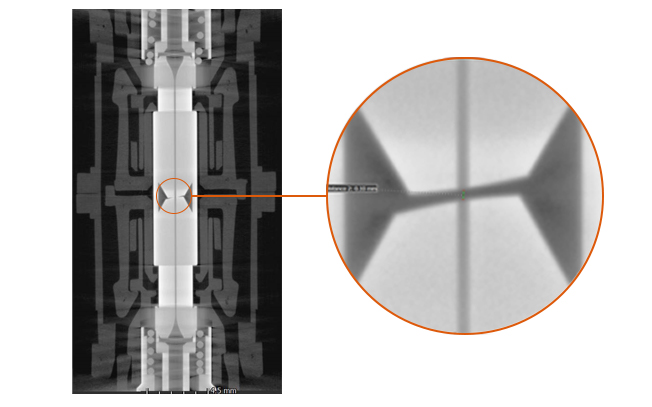

In the event of a connectivity issue in the presence of saliva, a tomography analysis is carried out to understand the loss of decibels and identify where in the adapter the defect is.

This technique helps reconstruct a solid with several X-ray pictures, a bit like an MRI.

When connection is compliant, the ferrules are in contact, as evidenced here:

SC-APC plugs in the adapter

Analyses on contaminated plugs show a gap between the ferrules. Saliva residue in the adapter prevents the bottom ferrule, in the picture, to get into the correct position:

Contaminated SC-APC plugs in the adapter

It can be seen that, when the plug is contaminated by saliva, the ferrule does not fit properly into the adapter, which prevents a good connection.

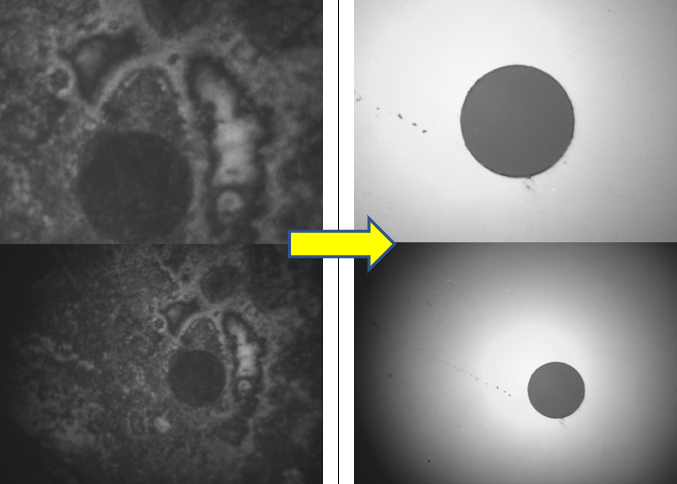

Under a microscope, at the tip of the plug, saliva-related contamination is clearly noticeable:

Before/after solvent cleaning

To properly clean plugs contaminated with saliva, it is advisable to use alcohol or a solvent, instead of the usual cleaning pen or cassette. It is apparent that saliva also contaminates the adapter. Using a stick is not enough to thoroughly clean this adapter.

Good practices to be shared with installers

In the hope of achieving an optimal connection result, the saliva deposit trick produces the opposite effect. When saliva dries, it causes poor connection and poses difficulties in the entire fiber-optic network. It is therefore necessary to inform installation and quality teams of the inefficiency of this practice, which is inconspicuous but detrimental to the entire network.

To effectively carry out measurements, the technician must verify the quality of the launch fiber under the microscope or by comparing fibers. Also systematically cleaning the plug of said launch fiber before and during the measurement campaign.

If the test reveals contamination, the 2 plugs of the connector must be cleaned. Depending on the type of impurity: pen or cassette for “basic” contamination, solvent cleaning for significant contamination. Dry cleaning is required after using a solvent.

In conclusion, it is important not to use saliva, because this causes significant malfunction in the short or medium term. And this practice generates customer dissatisfaction for all operators and a negative image of the profession of technician.